Move-In Appliance Inspection Checklist: What Vancouver Homeowners Should Test Before Unpacking

Thinking about skipping that detailed appliance check before settling into your new Vancouver home? Hold up – those seemingly functional appliances could be hiding costly surprises that only show up after you’ve already unpacked your life.Moving into a new home is exciting enough without discovering your brand-new dishwasher doesn’t actually clean dishes or your dryer takes three hours to dry a single load. I remember helping my friend Sarah move into her dream condo in Yaletown, only to discover three days later that the gorgeous stainless steel refrigerator had been slowly leaking water behind the kitchen island for months. What started as move-in bliss quickly turned into expensive floor repairs and a massive insurance headache that could have been completely avoided with proper pre-move testing.  Here’s the thing about Vancouver’s housing market – whether you’re buying or renting, appliances often come with the territory, and standard home inspections frequently gloss over detailed appliance functionality. While your home inspector might note that appliances are “present and appear functional,” they’re typically not testing every cycle, checking temperature accuracy, or identifying those subtle warning signs that spell trouble down the road. Vancouver’s coastal climate adds another layer of complexity, with our notorious humidity creating perfect conditions for hidden moisture damage and accelerated wear issues that don’t show up in basic visual inspections.The truth is, most people assume included appliances work perfectly because they look good and turn on when tested briefly during viewings. But appliances are complex machines with multiple systems that can fail independently, and some issues only become apparent during extended use or under specific conditions. Taking the time to thoroughly test every appliance before you commit to living with potential problems isn’t being paranoid – it’s being smart about protecting your investment and avoiding the kind of unexpected expenses that can derail your moving budget.

Here’s the thing about Vancouver’s housing market – whether you’re buying or renting, appliances often come with the territory, and standard home inspections frequently gloss over detailed appliance functionality. While your home inspector might note that appliances are “present and appear functional,” they’re typically not testing every cycle, checking temperature accuracy, or identifying those subtle warning signs that spell trouble down the road. Vancouver’s coastal climate adds another layer of complexity, with our notorious humidity creating perfect conditions for hidden moisture damage and accelerated wear issues that don’t show up in basic visual inspections.The truth is, most people assume included appliances work perfectly because they look good and turn on when tested briefly during viewings. But appliances are complex machines with multiple systems that can fail independently, and some issues only become apparent during extended use or under specific conditions. Taking the time to thoroughly test every appliance before you commit to living with potential problems isn’t being paranoid – it’s being smart about protecting your investment and avoiding the kind of unexpected expenses that can derail your moving budget.

Key Outtakes:

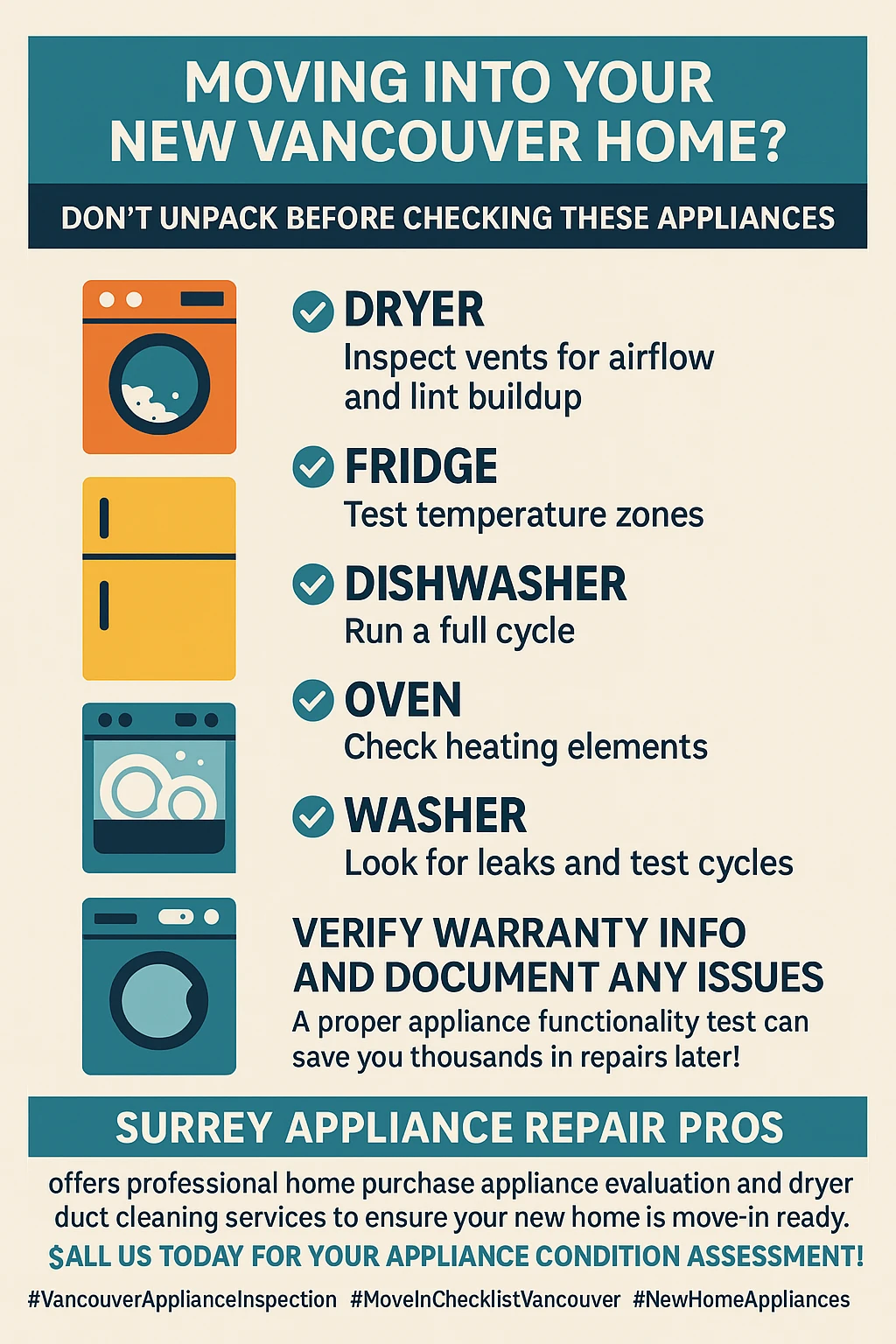

- Standard home inspections often miss appliance functionality issues that could cost thousands in repairs after moving in

- Testing every appliance cycle and function before unpacking protects your investment and prevents move-in day surprises

- Vancouver’s humid coastal climate requires special attention to dryer vent maintenance and appliance moisture damage prevention

- Professional appliance testing during inspection can reveal safety hazards like electrical issues and fire risks

- Proper documentation and warranty verification during move-in creates legal protection for both buyers and renters

Understanding Vancouver’s Unique Appliance Challenges

Before diving into specific testing protocols, it’s crucial to understand why Vancouver homes require extra attention when it comes to appliance inspection. Our coastal location creates a perfect storm of conditions that can accelerate appliance wear and create problems you won’t find in drier climates or inland cities. The combination of salt air, high humidity levels, and temperature fluctuations puts additional stress on appliance components, particularly metal parts prone to corrosion and electrical connections that can degrade faster in moisture-rich environments.  Vancouver’s housing density also creates unique considerations for appliance performance and safety. Many homes feature appliances in compact spaces with limited ventilation, making proper airflow and moisture management even more critical. Condo buildings and older homes often have shared ventilation systems or outdated electrical infrastructure that can affect appliance performance in ways that aren’t immediately obvious during a quick viewing. Understanding these environmental factors helps explain why thorough pre-move appliance testing isn’t just recommended – it’s essential for protecting your investment and ensuring your family’s safety.The city’s competitive rental and housing markets add another layer of complexity to appliance inspection. With properties moving quickly and limited time for detailed inspections, many buyers and renters feel pressured to skip thorough appliance testing. However, this rush to secure housing can lead to expensive surprises that far exceed the time and cost of proper pre-move inspection. Vancouver’s legal framework also creates specific responsibilities around appliance maintenance and replacement that vary depending on whether you’re buying or renting, making it crucial to understand exactly what you’re getting into before signing on the dotted line.Climate-related appliance issues in Vancouver often develop gradually and may not be apparent during brief testing periods. Moisture problems that eventually lead to mold, rust, or electrical issues might show no immediate symptoms but can cause significant damage over time. Similarly, efficiency problems caused by salt air corrosion or humidity-related wear might only become apparent when you receive your first utility bill or notice appliances struggling to maintain proper performance. This is why comprehensive testing that goes beyond basic functionality checks is so important for Vancouver homeowners.The good news is that understanding these regional challenges allows you to focus your inspection efforts on the most vulnerable areas and systems. By prioritizing moisture-related issues, electrical connections, ventilation systems, and efficiency metrics during your appliance inspection, you can identify potential problems before they become expensive headaches. This targeted approach ensures you’re not just checking that appliances turn on and off, but actually verifying they can perform reliably in Vancouver’s specific environmental conditions.

Vancouver’s housing density also creates unique considerations for appliance performance and safety. Many homes feature appliances in compact spaces with limited ventilation, making proper airflow and moisture management even more critical. Condo buildings and older homes often have shared ventilation systems or outdated electrical infrastructure that can affect appliance performance in ways that aren’t immediately obvious during a quick viewing. Understanding these environmental factors helps explain why thorough pre-move appliance testing isn’t just recommended – it’s essential for protecting your investment and ensuring your family’s safety.The city’s competitive rental and housing markets add another layer of complexity to appliance inspection. With properties moving quickly and limited time for detailed inspections, many buyers and renters feel pressured to skip thorough appliance testing. However, this rush to secure housing can lead to expensive surprises that far exceed the time and cost of proper pre-move inspection. Vancouver’s legal framework also creates specific responsibilities around appliance maintenance and replacement that vary depending on whether you’re buying or renting, making it crucial to understand exactly what you’re getting into before signing on the dotted line.Climate-related appliance issues in Vancouver often develop gradually and may not be apparent during brief testing periods. Moisture problems that eventually lead to mold, rust, or electrical issues might show no immediate symptoms but can cause significant damage over time. Similarly, efficiency problems caused by salt air corrosion or humidity-related wear might only become apparent when you receive your first utility bill or notice appliances struggling to maintain proper performance. This is why comprehensive testing that goes beyond basic functionality checks is so important for Vancouver homeowners.The good news is that understanding these regional challenges allows you to focus your inspection efforts on the most vulnerable areas and systems. By prioritizing moisture-related issues, electrical connections, ventilation systems, and efficiency metrics during your appliance inspection, you can identify potential problems before they become expensive headaches. This targeted approach ensures you’re not just checking that appliances turn on and off, but actually verifying they can perform reliably in Vancouver’s specific environmental conditions.

Essential Kitchen Appliance Testing Protocol

Moving from understanding Vancouver’s unique challenges to practical testing protocols, your kitchen appliances deserve first priority in any comprehensive inspection checklist. These hardworking machines see daily use and represent significant replacement costs if they fail prematurely. The key to effective kitchen appliance testing lies in going far beyond the basic “does it turn on” approach that many people rely on during home viewings.Start your refrigerator assessment by checking temperature consistency across all zones, including the main compartment, crisper drawers, and freezer section. Use a reliable thermometer to verify that the refrigerator maintains 37-40°F and the freezer stays at 0°F or below. Temperature inconsistencies often indicate failing thermostats, damaged door seals, or compressor issues that aren’t immediately obvious but will lead to food spoilage and higher energy bills. Pay special attention to the door seals by performing the dollar bill test – close a dollar bill in the door and try to pull it out. If it slides out easily, the seals need replacement.Don’t overlook the refrigerator’s mechanical components during your inspection. Refrigerators that are overworked and close to breaking down will have very hot coils, so check the condenser coils for excessive heat, dust buildup, or signs of damage. Listen for unusual noises like grinding, clicking, or excessive humming that could indicate motor problems. Also verify that the ice maker and water dispenser function properly if equipped, as these features involve complex plumbing that can develop leaks or clogs over time.Your range and oven testing should be methodical and comprehensive, covering every burner, oven function, and safety feature. Test each stovetop burner at multiple heat settings, watching for uneven heating patterns, delayed ignition, or flames that appear yellow or orange instead of blue on gas units. For electric ranges, ensure heating elements get uniformly red and maintain consistent temperatures. Test the temperature of the oven by hanging an oven thermometer within the oven and allowing it to heat, checking the temperature inside matches the temperature displayed on the control panel.  Oven functionality testing should include both baking and broiling functions, along with any specialty features like convection or self-cleaning cycles. Check that oven doors seal properly and that interior lights work correctly. Don’t forget to test important safety features like automatic shut-offs and ensure that all control knobs and digital displays function properly. For gas ranges, verify that safety features like flame failure devices work correctly – the gas should shut off automatically if flames are extinguished accidentally.Dishwasher testing requires running a complete wash cycle to identify potential problems that won’t show up during brief demonstrations. We run the dishwasher through a full cycle, making sure the fill and drain stages work properly, and that there’s no leakage from the unit. Load the dishwasher with actual dishes if possible, or at least some dishwasher-safe items, and run a normal cycle using standard detergent. This comprehensive test reveals problems with spray arm operation, drainage issues, heating element function, and cleaning effectiveness that you can’t assess from simple visual inspection.During the dishwasher cycle, pay attention to water temperature, noise levels, and any unusual sounds or vibrations. Check for leaks around the door seals, beneath the unit, and at all connection points. Verify that the dishwasher properly drains and that the final rinse cycle leaves dishes clean and spot-free. Also test the garbage disposal if your dishwasher drains through it, as disposal clogs can cause dishwasher drainage problems that might not be apparent until after you’ve moved in and started regular use.

Oven functionality testing should include both baking and broiling functions, along with any specialty features like convection or self-cleaning cycles. Check that oven doors seal properly and that interior lights work correctly. Don’t forget to test important safety features like automatic shut-offs and ensure that all control knobs and digital displays function properly. For gas ranges, verify that safety features like flame failure devices work correctly – the gas should shut off automatically if flames are extinguished accidentally.Dishwasher testing requires running a complete wash cycle to identify potential problems that won’t show up during brief demonstrations. We run the dishwasher through a full cycle, making sure the fill and drain stages work properly, and that there’s no leakage from the unit. Load the dishwasher with actual dishes if possible, or at least some dishwasher-safe items, and run a normal cycle using standard detergent. This comprehensive test reveals problems with spray arm operation, drainage issues, heating element function, and cleaning effectiveness that you can’t assess from simple visual inspection.During the dishwasher cycle, pay attention to water temperature, noise levels, and any unusual sounds or vibrations. Check for leaks around the door seals, beneath the unit, and at all connection points. Verify that the dishwasher properly drains and that the final rinse cycle leaves dishes clean and spot-free. Also test the garbage disposal if your dishwasher drains through it, as disposal clogs can cause dishwasher drainage problems that might not be apparent until after you’ve moved in and started regular use.