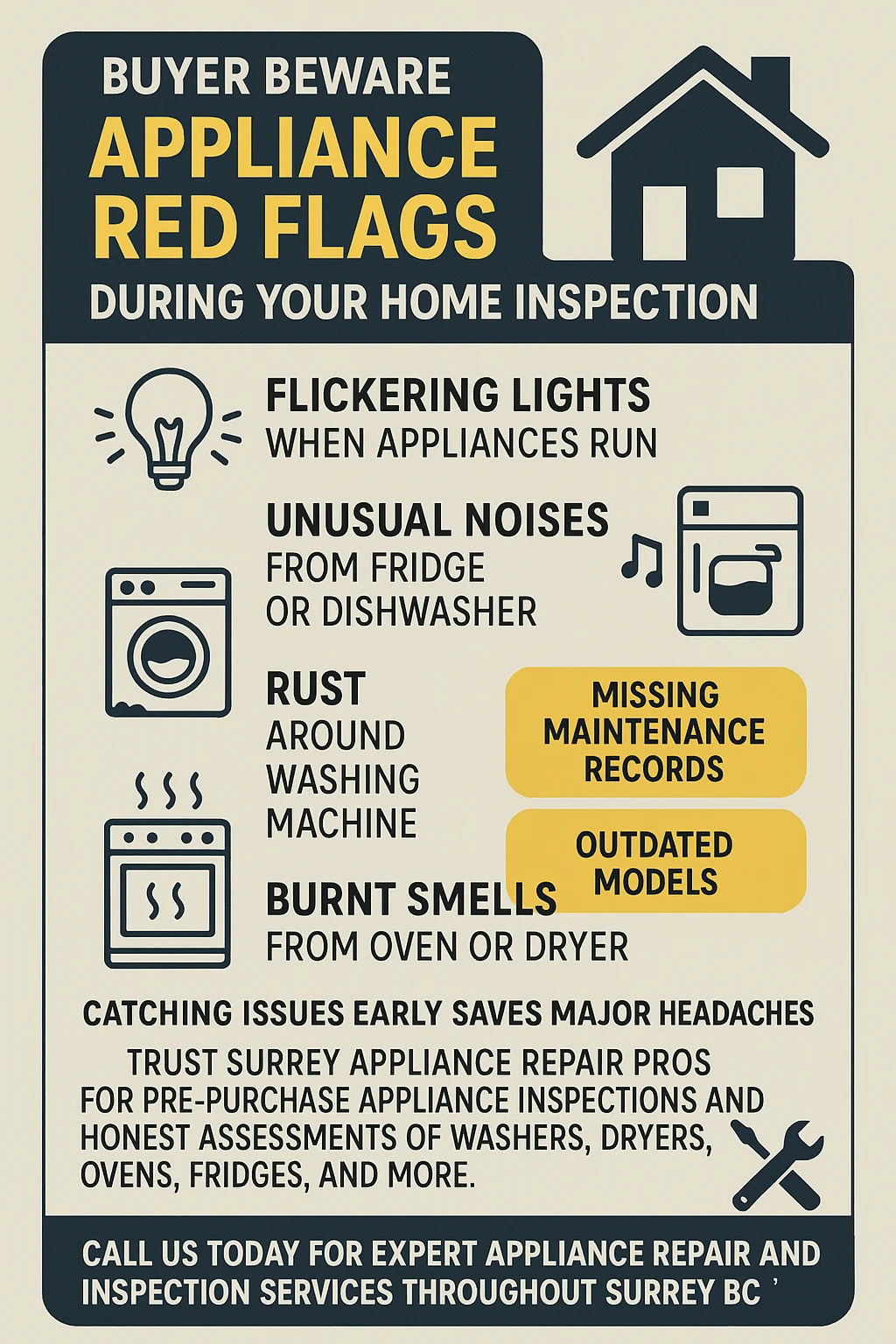

Thinking about buying a home in Surrey and wondering what appliance red flags could cost you thousands after closing? Discover the critical warning signs that even experienced home inspectors often miss, and learn how to protect yourself from costly surprises that could drain your budget within months of moving in.

Purchasing a home represents one of life’s most significant investments, yet many buyers focus primarily on structural elements while overlooking critical appliance warning signs that can lead to expensive repairs shortly after closing. In Surrey’s competitive real estate market, understanding appliance red flags during home inspections can save homeowners thousands of dollars and prevent safety hazards that threaten family well-being.

While standard home inspections provide valuable insights into overall property condition, they often miss subtle appliance issues that manifest only with regular use. Research indicates that approximately forty-seven percent of new homeowners encounter appliance problems within their first year of ownership, making comprehensive pre-purchase appliance assessment an essential component of informed home buying decisions.

Key Outtakes:

- Standard home inspections may not comprehensively test all appliances, leaving buyers vulnerable to expensive post-closing surprises

- Gas appliances require specific safety assessments including leak detection and proper ventilation verification

- Water-related appliances like dishwashers and washing machines pose significant water damage risks if leaking or improperly installed

- Electrical safety violations involving appliances can create fire hazards and insurance coverage issues

- Regional factors in Surrey’s coastal climate accelerate appliance deterioration and require enhanced maintenance awareness

Understanding Home Inspection Limitations and Appliance Assessment Scope

Many Surrey homebuyers assume that a standard home inspection provides comprehensive evaluation of all appliances included with their purchase. However, the scope of appliance testing during typical inspections often proves more limited than buyers expect. Home inspectors typically perform basic operational checks rather than in-depth technical evaluations, testing whether appliances turn on and appear to function without conducting extended performance assessments that might reveal intermittent problems.

The American Society of Home Inspectors Standards of Practice Section 10.1.F specifically states that inspectors are not required to inspect refrigerators, clothes washing machines, or clothes dryers. This means that while many inspectors choose to include these appliances in their assessments, the depth and thoroughness of testing varies significantly between individual inspectors and companies. When an inspector tests an oven, they might operate it briefly to verify basic functionality, but they won’t conduct extended heating tests or precision temperature calibrations that could identify performance inconsistencies.

Additionally, home inspections represent snapshots of appliance condition at specific moments rather than comprehensive performance evaluations over time. Appliances that function properly during a brief inspection can develop serious problems within weeks of purchase, particularly if they’re operating near the end of their useful lives or have underlying issues that only manifest under regular use conditions.

Critical Kitchen Appliance Red Flags

Understanding the specific warning signs in kitchen appliances helps buyers identify potential problems before they become expensive post-purchase headaches. Kitchen appliances represent some of the most costly household equipment to repair or replace, making careful pre-purchase assessment particularly important for protecting your investment.

Range and Oven Warning Signs

Gas ranges present unique inspection challenges because they involve both electrical and gas components, creating multiple potential failure points. When evaluating a gas range, listen carefully for clicking or ticking sounds during ignition, watch for flame color and consistency, and verify that burners ignite smoothly without excessive delay. Weak yellow or orange flames instead of predominantly blue flames indicate improper gas mixture or burner problems requiring professional attention.

Temperature accuracy represents another critical concern often missed during brief inspections. Consumer Reports research indicates that approximately six percent of consumers report oven heating problems within the first few years of ownership. Bringing an oven thermometer to home showings and testing actual versus displayed temperatures can reveal calibration issues that affect cooking performance and energy efficiency.

Electric ranges show different failure patterns than gas models, with heating elements and control systems representing the most common problem areas. Watch for heating elements that glow unevenly, take excessive time to heat, or show visible damage like cracks or warping. Control knobs should turn smoothly and correspond accurately to heating levels, while digital displays should appear clear and respond appropriately to input commands.

Refrigerator Assessment Beyond Basic Cooling

Refrigerator evaluation requires moving far beyond simply confirming that cold air comes from the unit when doors open. Temperature consistency across all zones indicates proper thermostat and circulation system function, with main compartments maintaining thirty-seven to forty degrees Fahrenheit and freezers staying at zero degrees or below. Use a reliable refrigerator thermometer to verify these temperatures rather than relying on built-in displays that may not reflect actual internal conditions.

Door seal integrity directly impacts energy efficiency and food preservation effectiveness. The dollar bill test provides a simple assessment method: closing a dollar bill in the refrigerator door should create significant resistance when attempting to pull it out, indicating proper seal compression. Loose or deteriorated seals allow warm air infiltration that forces compressors to work continuously, increasing energy costs and reducing component lifespan.

Water and ice dispensers involve complex internal plumbing that frequently develops problems, with Consumer Reports indicating that seventeen percent of respondents experience dispenser failures. Test water flow rate and consistency, verify ice cube formation and dispensing, and check for any unusual tastes or odors that might indicate filter problems or water line contamination. Non-functioning dispensers often indicate broader internal plumbing issues requiring expensive professional repair.

Dishwasher Defects and Water Damage Risks

Building on kitchen appliance concerns, dishwashers deserve particular attention due to their potential for causing extensive water damage beyond simple appliance repair costs. Understanding dishwasher-specific warning signs helps buyers avoid the catastrophic expenses associated with undetected leaks that can damage flooring, cabinetry, and structural elements.

Water leak detection requires running full wash cycles rather than simply verifying that machines turn on. Position yourself where possible to observe the dishwasher’s base and connection points during operation, watching for any water seepage that indicates seal failures or loose connections. Research indicates that dishwasher leaks can cause water damage cleanup costs ranging from three hundred to twenty-five hundred dollars for average kitchen spaces, far exceeding the cost of dishwasher replacement.

Installation level significantly affects dishwasher performance and longevity, as improperly leveled units cannot drain effectively. Standing water inside dishwashers encourages mold and mildew growth while potentially damaging internal components. Listen for proper fill and drain sounds during test cycles, verify complete drainage after cycles finish, and ensure that dishes emerge clean without excess moisture or spotting that indicates performance problems.

Door gaskets represent one of the most common failure points, with normal wear gradually degrading rubber or silicone materials until they no longer form watertight seals. Examine gaskets visually for cracks, brittleness, or separation from door frames, and test seal integrity by checking whether doors close firmly without gaps. Additionally, verify that drain hoses are properly looped and elevated above garbage disposal entry points to prevent backflow during operation.

Laundry Equipment Safety and Performance Issues

Transitioning from kitchen appliances to laundry equipment, washing machines and dryers present their own unique sets of potential problems that can affect both functionality and safety. These appliances account for significant portions of post-closing repair expenses, particularly when buyers fail to identify warning signs during the inspection process.

Washing Machine Assessment

Front-load washing machines offer superior cleaning performance compared to top-load models but present unique challenges including susceptibility to mold and mildew growth. Consumer Reports data indicates that approximately fourteen percent of front-load washer owners report visible mold growth, particularly around rubber gaskets that trap moisture. Pull back door gaskets during inspection to examine crevices where water collects, looking for any visible mold, mildew, or musty odors.

Water drainage assessment requires testing complete wash cycles to verify that water drains fully from tubs without leaving standing water in drum bottoms. Check drain hose connections for security, visible cracks, or deterioration that could lead to water damage. Washing machine drain hose failures represent common causes of significant residential water damage, as burst or disconnected hoses can flood entire laundry rooms and penetrate floors or walls.

Inlet hose condition directly affects flood risk, with many insurance policies requiring hose replacement every five to ten years as preventive maintenance. Examine inlet hoses for visible corrosion, cracking, or bulging that indicates imminent failure risk. Modern braided stainless steel hoses provide superior durability compared to older rubber hoses, and their presence suggests recent maintenance attention that reduces immediate failure likelihood.

Dryer Fire Safety Concerns

Clothes dryer inspection requires particular attention to fire prevention, as dryer-related fires cause approximately thirty-five million dollars in property damage annually. Verify that dryers actually heat during operation, that lint traps are clean and properly seated, and that exhaust vents terminate at exterior walls rather than in attics or crawlspaces where lint accumulation creates fire hazards.

Vent system design significantly impacts safety, with accordion-style flexible vents representing particular hazards due to their tendency to sag and collect lint in low areas. Rigid metal ducts with smooth interior walls reduce lint buildup and fire risk compared to flexible alternatives. During inspection, ask whether exterior vent operation was verified by observing exhaust airflow from outside vent openings while dryers operate.

Gas dryers require additional safety assessment to ensure no gas odors during operation and proper gas line connections. Listen for grinding, squeaking, or excessive rattling that suggests worn drum components requiring replacement. Dryers should operate relatively quietly and complete normal drying cycles within reasonable timeframes rather than requiring multiple cycles for complete drying.

Electrical Safety and Code Compliance Issues

Moving beyond mechanical appliance assessment, electrical safety represents a critical concern that can affect both appliance performance and overall home safety. Electrical defects related to appliances create risks including house fires, electrocution, and electrical system failures that can prove both dangerous and expensive to remedy.

Electrical safety assessment should identify exposed or frayed wires, burn marks around outlets and switches, improper wire splicing indicating DIY electrical work, and sparking or buzzing when plugging in appliances. These issues prove particularly common in older homes where appliances may have been added without updating electrical systems to handle modern power demands.

Major appliance electrical requirements often exceed the capacity of standard power strips and extension cords, creating fire risks when homeowners use inappropriate electrical connections. Microwaves typically draw between one thousand and fifteen hundred watts, far exceeding safe power strip limits. Refrigerators, freezers, and electric ranges should connect directly to dedicated wall outlets with proper circuit capacity rather than through power strips or extension cords.

Outdated electrical panels in older homes may lack modern safety features like arc-fault circuit-interrupter protection required by current building codes. Fuse boxes instead of circuit breaker panels indicate electrical systems that likely don’t meet current standards, potentially affecting homeowners insurance availability and requiring costly upgrades. Many insurance policies refuse coverage for homes with outdated electrical systems until they’re updated to current safety standards.

Water Damage Prevention and Plumbing Assessment

Expanding on water-related safety concerns, comprehensive appliance assessment must include evaluation of water supply and drainage systems that support appliance operation. Water damage represents the third-largest cause of property damage in North America, with appliances contributing significantly to this problem through supply line failures and drainage issues.

Plumbing system evaluation should identify cracked water pipes, corroded connections, inadequate water pressure, visible rust on exposed pipes, and drainage concerns that could affect appliance performance. During appliance testing, observe any leaking during operational cycles, verify secure drain hose connections, and ensure water doesn’t pool near foundations or in other concerning locations.

Garbage disposal systems frequently develop drainage problems that cascade into broader plumbing issues affecting dishwashers and other connected appliances. Garbage disposals aren’t designed for all food waste types, with items like banana peels, coffee grounds, pasta, rice, and fibrous vegetables capable of creating blockages that prevent proper drainage throughout connected systems. Test disposals for smooth operation without jamming and verify proper drainage after operation.

Drain system design impacts multiple appliances simultaneously, as dishwashers discharge through connection points that can become clogged when garbage disposal blockages exist, while washing machine drain lines can backup when downstream plumbing becomes obstructed. Look for signs of previous water backup, flooding, or drainage problems in basements or laundry rooms that indicate chronic issues likely to recur with continued appliance use.

Regional Climate Factors Affecting Surrey Appliances

Surrey’s coastal British Columbia location creates specific environmental challenges for appliances that differ significantly from inland or drier regions. Understanding these regional factors helps buyers make informed decisions about appliance condition assessment and long-term maintenance requirements in local climate conditions.

Humidity levels in coastal environments accelerate corrosion of metal appliance components while encouraging mold and mildew growth that progresses more rapidly than in drier climates. Front-load washing machines require particular attention in humid coastal areas because their moisture-trapping design becomes especially problematic when ambient humidity levels already remain elevated. The Home Inspectors Association of British Columbia emphasizes that regional climate factors should influence inspection priorities and post-purchase maintenance planning.

Salt air exposure near coastal areas creates additional corrosion risks for electrical appliances, requiring more frequent inspection and maintenance than identical units in inland locations. Dryer vent systems in British Columbia particularly require professional inspection at least annually because winter weather conditions can obstruct exterior vent openings more frequently than in milder climates.

Older homes prevalent in many Surrey neighborhoods may have electrical systems that don’t meet current building codes, and aging appliances may lack proper grounding or modern safety features standard in newer construction. Buyers should research local appliance repair service availability and costs, as these factors affect long-term ownership expenses and decisions about whether to repair or replace aging equipment.

Frequently Asked Questions

What appliances should definitely be tested during a Surrey home inspection?

All major built-in appliances should be tested including ranges, ovens, dishwashers, garbage disposals, and any refrigerators or laundry equipment included with the home purchase. Focus particularly on appliances involving gas connections, water supply lines, or electrical systems that could create safety hazards if malfunctioning. Request that your inspector run full operational cycles rather than simply verifying that appliances turn on.

Even when appliances aren’t technically required to be inspected under standard protocols, comprehensive testing provides valuable information about condition and remaining useful life. Consider hiring specialized appliance technicians for high-value items if the standard inspection raises any concerns about performance or safety.

How can I tell if an appliance problem is serious enough to negotiate with sellers?

Safety issues involving gas leaks, electrical hazards, or water damage risks should always be addressed through negotiations, as these create liability concerns and immediate repair needs. Functional problems affecting appliance performance may warrant negotiation depending on repair costs relative to the appliance’s age and expected remaining lifespan.

Document all identified problems with photographs and obtain repair estimates from qualified technicians to support negotiation discussions. Problems that could cost more than a few hundred dollars to repair generally justify requesting seller credits or repairs, particularly when they affect essential appliances like refrigerators or primary cooking equipment.

What should I do if my home inspector missed a significant appliance problem?

Review your inspection agreement and report carefully to understand what was actually assessed and whether the missed issue falls within the inspector’s stated scope of practice. If the inspector followed established standards and the problem wasn’t apparent during visual inspection, legal recourse may be limited.

However, if you can demonstrate that the inspector failed to follow professional standards or was negligent in their assessment, you may have grounds for claims involving breach of contract or professional malpractice. Documentation from the inspection day including photographs and written notes becomes critical evidence for any potential claims against inspectors or sellers.

Are home warranties worth buying for appliance protection?

Home warranties can provide valuable financial protection against unexpected appliance failures, particularly for buyers purchasing homes with aging appliances. These warranties typically cover repair or replacement costs for major appliances and systems due to normal wear and tear, with homeowner responsibility limited to service call fees ranging from fifty to one hundred fifty dollars per visit.

Home warranty coverage proves particularly beneficial for older appliances approaching the end of their expected lifespans, as repair costs for aging equipment often exceed replacement costs. However, warranties typically include waiting periods and may not cover pre-existing conditions, making it important to purchase coverage immediately after closing rather than waiting until problems develop.

Wrapping Up

Comprehensive appliance assessment during Surrey home inspections represents an essential investment in protecting your home purchase from costly post-closing surprises. While standard inspections provide valuable baseline information, informed buyers must take proactive steps to identify appliance warning signs that could result in expensive repairs or safety hazards shortly after moving in. By understanding the specific red flags associated with kitchen appliances, laundry equipment, electrical systems, and water-related components, you can make informed decisions about negotiating repairs or seeking additional professional assessments before finalizing your purchase.

At Surrey Appliance Repair Pros, we understand the importance of thorough appliance evaluation for new homeowners throughout the Lower Mainland. Our experienced technicians provide comprehensive pre-purchase appliance inspections that go beyond standard home inspection protocols, identifying potential problems and providing detailed assessments of remaining appliance lifespans. Whether you need professional appliance testing before closing or expert repair services after discovering problems in your new Surrey home, our team delivers reliable solutions that protect your investment and ensure your family’s safety and comfort.